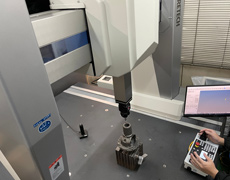

While castings are often perceived as lacking in strength, Senshu achieves the production of high-strength castings using premium spheroidal graphite cast iron (ductile iron).

Automotive-related fields

As the automotive industry advances, manufacturing technologies for each component continue to demand increasingly high standards. At Senshu, we produce parts requiring “reliable high strength and precision,” such as those for the brake system. We achieve high strength through ductile iron and pursue further weight reduction through research in casting technology.