We recognize that customer expectations will inevitably continue to rise.

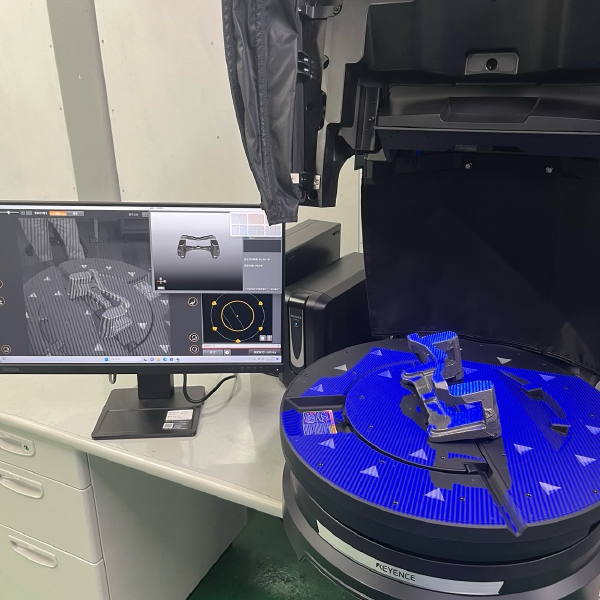

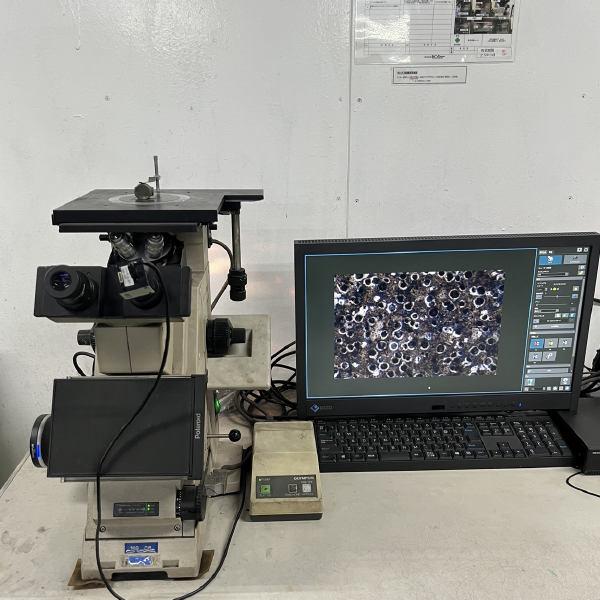

Therefore, we actively pursue both the enhancement of inspection techniques and investment in equipment.

Here, we introduce our inspection system that guarantees high strength and high quality.

Composition Inspection

We measure the composition of molten metal dissolved in the high-frequency furnace using a CE meter and vacuum-type kant recorder at the furnace front, managing composition control.